This is the third article in a series looking at why oil trains derail at higher rates than ethanol trains. More ethanol was moved by rail from 2010–2015 than oil, but oil trains derail at a higher rate and with more severe consequences. Part one addressed train length as a factor and part two addressed “sloshing.”

On January 25, 2011, a notice appeared in the Federal Register announcing a change in the rules on allowable weight for a rail tank car transporting hazardous materials. It declared the Federal Railroad Administration’s (FRA) approval to increase this weight limit, bumping it up to 286,000 pounds gross rail load (GRL) from the previous limit of 263,000 pounds.

Perhaps it was just a coincidence, but this rule change was well-timed for the Bakken oil-by-rail boom that was taking off at that point. Regardless, it had immediate impacts on the ability of the industry to move oil in long unit trains with cars that were heavier than previously allowed.

Prior to 2011, the largest volume of hazardous materials being moved by rail was ethanol and most of that was in tank cars with a gross rail load of 263,000 pounds, meaning the weight of the tank car plus the weight of the contents could not exceed this amount. However, this rule change allowed for crude oil to move tank cars with heavier loads, and the industry took advantage of that.

In July 2016 at a National Transportation Safety Board (NTSB) roundtable meeting on “What’s Next in Rail Tank Car Safety,” Richard Kloster of rail consulting firm Alltranstek, explained the change:

“So we started out with the 30,000 gallon 263,000 pound capacity gross rail load car during the ethanol cycle. Than when CPC-1232 came in, that was when the Bakken was hot. And so the Bakken crude is more of a light sweet [crude] … [it] didn’t require coils and insulation. So the cars were scaled up to 286. And that meant that 30,000 gallons jumped to 31,800.”

Thanks to that rule change and the production of new CPC-1232 tank cars with larger capacity, trains carrying Bakken crude oil became heavier than the ethanol trains, using a new class of heavier tank cars traveling in dedicated unit trains of more than 100 tank cars.

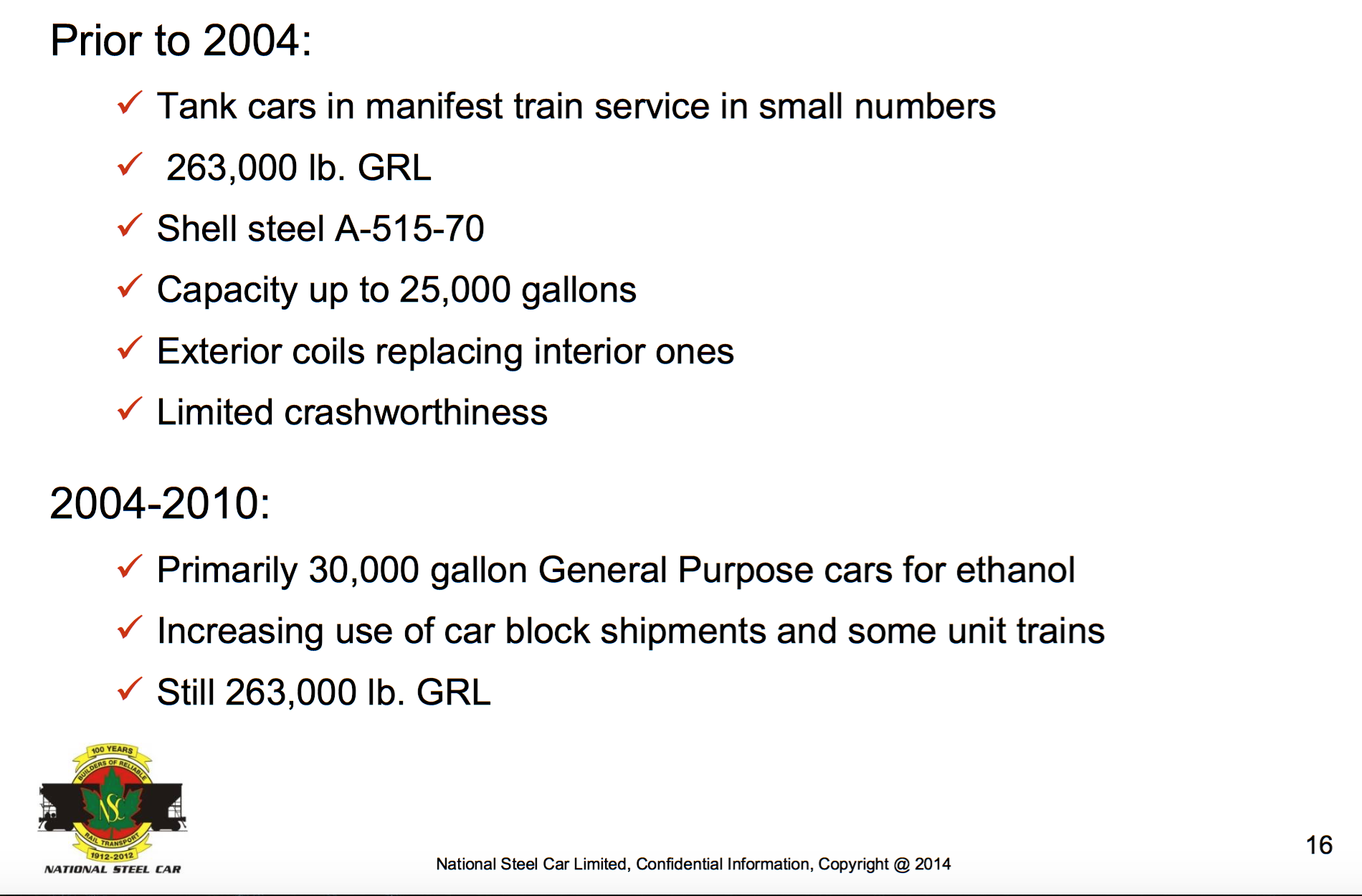

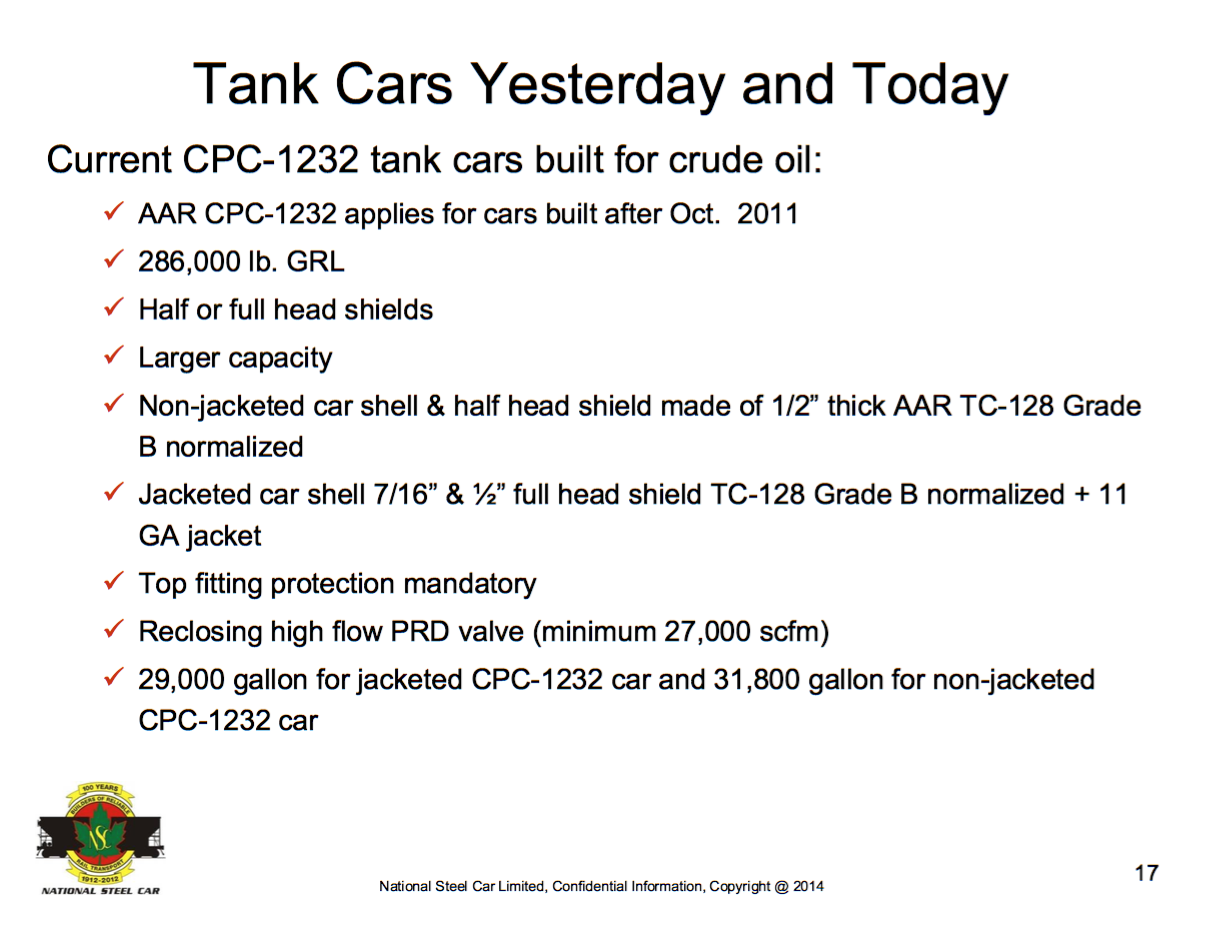

This change was also explained in two slides from a presentation titled, “The Tank Car Story: A Builder’s Perspective,” that was presented to the Northeast Association of Rail Shippers. The first slide shows that prior to 2010, the tank cars were operating with weight limits of 263,000 pounds for a loaded car.

The next slide shows that starting in late 2011, oil trains began operating with tank cars with limits of 286,000 pounds for a loaded car.

When, in late 2011, industry started shipping Bakken oil in the new 286,000-pound cars via long unit trains, a new era of rail tank car transportation began. And a mere two years later, as oil-by-rail started to reach signficant volumes, the risks of these bomb trains became more and more clear, with derailments and fires occurring in places including Lac-Mégantic, Quebec; Aliceville, Alabama; and Casselton, North Dakota (and those were just in 2013).

“These Trains Are Likely Too Long, Too Heavy”

As oil train derailments continued to happen, more people began to express concerns about the weight of these trains as a possible contributing factor in derailments.

Doug Finnson, president of the Teamsters Rail Conference of Canada, expressed concerns about the size and weight of the oil trains to CBC News after an oil train derailment in Canada in 2015, saying, “These trains are likely too long, too heavy, and going too fast for the track conditions in place.”

And the Los Angeles Times reported in 2015 that investigators at Canada’s Transportation Safety Board suspected that the oil trains are causing unusual track damage.

“Petroleum crude oil unit trains transporting heavily loaded tank cars will tend to impart higher than usual forces to the track infrastructure during their operation,” the safety board said in a report. “These higher forces expose any weaknesses that may be present in the track structure, making the track more susceptible to failure.”

Excessive weight was thought to be a contributing factor in the recent oil train accident in Mosier, Oregon. That accident was caused when the bolts holding the rails in place sheared off.

As Desmog reported at the time, there is precedent for this issue, according to rail consultant and former industry official Steven Ditmeyer. In the early 1990s, a similar problem was happening with some double-stacked container cars being too heavy for the infrastructure — because of overloaded containers — and resulting in sheared rail spikes.

“This sounds like a very similar circumstance to what was happening in the early 1990s with overloaded double stack container cars,” Ditmeyer told DeSmog.

That issue was resolved when the industry started weighing the cars to make sure no cars were over the weight limit. However, this isn’t done with rail cars transporting crude oil.

Hal Gard is the rail and public transit administrator for the Oregon Department of Transportation. After the accident in Mosier, he commented on the weight of the oil trains to the Associated Press, saying, “The unit trains are big and very heavy, the cars are shorter, and the oil is sloshing around inside of those cars. Are there additional strains and dynamic forces associated with that that is different?”

These 286,000 pound cars are clearly heavier than the 263,000 pound cars used to move ethanol and oil prior to late 2011. There is no question that they are creating greater forces on the tracks than the lighter cars. Is this what is contributing to the higher rates of derailments today?

Federal Railroad Administration Concerned About Train Weight in 2013

In the weeks following the oil train disaster in Lac-Megantic, people began asking a lot of important questions.

Some of these questions were posed by the Federal Railroad Administration (FRA) in a July 2013 letter to the American Petroleum Institute (API).

In the July 2013 letter, Thomas J. Herrmann, Acting Director of the Office of Safety Assurance and Compliance addressed API CEO Jack Gerard, outlining several safety concerns regarding oil trains, including the following:

FRA notes that tank cars overloaded by weight are typically identified when the tank cars go over a weigh-in-motion scale at a railroad’s classification yard. As indicated above, crude oil is typically moved in unit trains, and the cars in a unit train do not typically pass over weigh-in-motion scales in classification yards.

This means we know that in 2013 the FRA was questioning the API about “tank cars overloaded by weight.” And also that in the same year, the FRA had information showing the oil industry wasn’t using weigh-in-motion scales to check loaded tank car weights.

And we also know that using scales to weigh containers before double stacking them solved the overloading problem in the 1990s. Even though oil tank cars were approved for the new weight of 286,000 pounds, the FRA was questioning if they might be even heavier due to “overloading by weight.”

What was the API’s response to this letter? The Federal Railroad Administration told DeSmog it will require a Freedom of Information Act (FOIA) request to get a copy of that response, a request which has been filed. Since our last FOIA request about oil trains took almost two years to get a response, we may not know for a while. The American Petroleum Institute did not respond to a request for a copy of the letter.

However, we do know that no one likes to pay to move air by rail. Empty space in a tank car translates to lost profits. Could the oil industry be overfilling the tanks to increase profit margins, resulting in cars that are “overloaded by weight”? We got some insight into this at the 2016 NTSB roundtable when Richard Kloster explained the economics of moving freight by rail.

“The point is that rail is a high fixed cost proposition. So to move that first pound of freight the railroad has already incurred probably 60% of its cost to move that car. And so what shippers of anything from crude to ethanol to soda ash to grain or whatever, transportation can make or break markets. So being able to utilize the full capacity of that car and get every pound or extra ton shipped, helps them make their margins and can make or break a sale.”

Because crude oil can be quite heavy, we can infer that these rail tank cars are not fully loaded with liquid before reaching the 286,000 pound limit, which would leave empty space in the tank cars. But how much empty space is the industry really leaving in these oil rail cars?

Would the oil industry ever put profits above safety?

Weight Differences: Ethanol Versus Bakken Crude Oil

Ethanol is a manufactured product that weighs 6.59 pounds per gallon. Crude oil is a raw material and can vary greatly across an area like the Bakken formation, which underlies parts of North Dakota and Montana in the United States, and Saskatchewan and Manitoba in Canada. A ConocoPhilips specifications sheet on Bakken crude gave a range of 5.83-8.58 pounds per gallon for Bakken crude oil.

Clearly, Bakken oil has the potential to be much heavier than ethanol, creating an opportunity for overloading tank cars with crude oil that isn’t an option with ethanol. At the NTSB round table, Greg Saxton, engineer for tank car company Greenbrier, explained that with ethanol being so light, it is possible to fill up the car before reaching the weight limit, saying, “In some cases you won’t be able to fully load that car to 286,000.”

But there is another factor about the ethanol industry that limits the car weights. Because ethanol is produced in rural areas where it may have to travel on tracks that aren’t rated to carry the heavier 286,000 pound class of tank cars, the industry is still using the lighter 263,000 pound tank cars.

Kelly Davis, director of regulatory affairs for the Renewable Fuels Association, an ethanol industry lobbying group, explained this to the NTSB roundtable:

“The ethanol industry is rural so we have plants that are restricted through bridges and other infrastructure projects that still will have to load at the 263 max pounds.”

On September 18, 2016, an ethanol unit train in Albany, New York was hauling DOT-111 cars rated for 263,000 pounds, which is clearly marked on the tank cars. (The weight of the empty tank car is 66,600 pounds. The maximum weight of material that can be loaded into it is 196,400 pounds. The combined total weight is 263,000 pounds.)

DOT-111 tank car as part of ethanol unit train Image credit: Justin Mikulka

However, in response to the Bakken shale boom, North Dakota upgraded many of its rail lines to handle the larger, heavier tank cars that would be carrying crude oil.

For multiple reasons, oil trains are likely to be heavier than ethanol trains. Even though ethanol was moving by rail in large quantities for several years before the oil-by-rail business even began, ethanol trains were not derailing as the oil trains have been, and no one was calling them bomb trains.

Is the higher rate of derailments for oil trains compared to ethanol trains evidence that perhaps 286,000 pound loaded tank cars are just too heavy for existing rail infrastructure? Should the rule change from 2011 be revisited?

The Great Bakken Oil-by-Rail Experiment

When hydraulic fracturing (fracking) technology unleashed a flood of crude oil from North Dakota, there was a slight problem. It was primarily in rural North Dakota. And there was very little infrastructure in place, such as pipelines or ports, to move that oil. As a result, the industry started trucking it out, but this wasn’t a good long term solution because as reported by The Globe and Mail, “The trucking frenzy was chewing up roads, driving accident rates to record highs, and infuriating local residents.”

The Canadian newspaper further reported in late 2013, “What should have been an economic miracle for North Dakota has instead been a logistical nightmare. Since 2009, the state has been producing oil faster than it can be shipped to refineries.”

The industry solved that problem by quickly constructing oil-by-rail loading facilities. However, what remains quite clear is that these new unit trains carrying volatile Bakken oil hit the rails without any serious study of the dangers they posed.

Bakken oil trains have several factors working against them in terms of safety. One is the obviously dangerous nature of the cargo that has helped earn these trains the nickname, “bomb trains,” due to their derailments causing dramatic fires and explosions. A second factor is that these trains are much longer than the average freight train. Another is that tank cars carrying oil have a greater potential for the phenomenon known as ”sloshing” than exists with ethanol cars.

Finally, thanks to the federal rule change in 2011 — which occurred in the midst of North Dakota’s “logistical nightmare” — Bakken oil trains were now heavier than what had been the standard for the ethanol industry.

Oil trains’ significantly higher rate of derailment than ethanol trains appears to reveal flaws in this oil-by-rail experiment, just as these heavier trains are more apt to reveal flaws in the track infrastructure.

Unfortunately, the continued existence of these dangerous trains has also revealed the very serious flaws in the existing regulatory system that is supposed to be protecting the American public. The title of the NTSB hearing in July was, “A Dialogue on What’s Next in Rail Tank Car Safety.” The answer appears to be “more accidents that could have been easily prevented.”

A similar hearing was held in 2014 and was run by Deborah Hersman, the head of the NTSB at the time. She resigned shortly after that meeting and made the following statement, “We know the steps that will prevent or mitigate these accidents. What is missing is the will to require people to do so.”

Hersman also explained the root of the problem:

“Follow the money. It all comes back to the money.”

Main image credit: Justin Mikulka

Subscribe to our newsletter

Stay up to date with DeSmog news and alerts